What Is Anhydrous Acetone Used For?

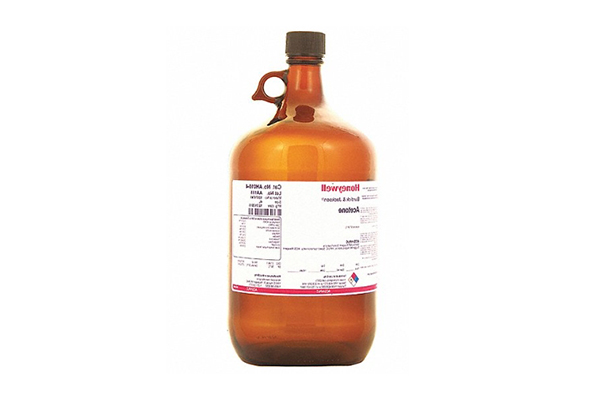

Acetone is a well-known solvent used across various industries, but when people refer to anhydrous acetone, they are speaking of a highly pure form of acetone that is completely free from water. This seemingly small difference—lack of water—makes anhydrous acetone especially valuable in sensitive chemical, industrial, and laboratory settings.

In this article, we’ll explore what anhydrous acetone is, how it differs from regular acetone, and most importantly, what it is used for.

What Is Anhydrous Acetone?

The term “anhydrous” means “without water.” So, anhydrous acetone is a pure, water-free version of standard acetone (chemical formula: C₃H₆O). While commercial-grade acetone may contain trace amounts of water, the anhydrous form has been specially processed—often through distillation or drying agents—to remove even minute moisture content. This is crucial in applications where the presence of water could cause unwanted reactions or reduced effectiveness.

Key Properties of Anhydrous Acetone

-

Highly volatile and flammable

-

Colorless with a distinct odor

-

Excellent solvent for organic compounds

-

Water-free, making it ideal for moisture-sensitive processes

Common Uses of Anhydrous Acetone

1. Organic and Inorganic Chemistry Laboratories

One of the most important uses of anhydrous acetone is in laboratory settings, particularly in organic synthesis. Many reactions are water-sensitive, meaning even small amounts of moisture can interfere with the chemical process. In such cases, using anhydrous acetone ensures:

-

Cleaner reaction environments

-

More reliable and consistent results

-

Better product yields

It’s especially useful when preparing Grignard reagents, which react violently with water. In such cases, the absolute dryness of all solvents—including acetone—is critical.

2. Drying and Cleaning Laboratory Equipment

Anhydrous acetone is commonly used to clean and dry glassware in labs because of its fast evaporation and water-free composition. It removes grease, oil, and moisture quickly and efficiently, leaving no residue behind. This makes it a go-to solvent for prepping equipment before sensitive experiments.

3. Electronics and Semiconductor Industry

In the electronics field, particularly in the manufacture of semiconductors and circuit boards, even a small amount of water can compromise the integrity of components. Anhydrous acetone is used to:

-

Clean silicon wafers

-

Remove organic residues

-

Dry components before further treatment or packaging

Because it evaporates quickly and doesn’t leave behind moisture, it is preferred over other solvents in many electronic applications.

4. Pharmaceuticals and Biotechnology

Anhydrous acetone is also used in the formulation and purification of pharmaceuticals. When preparing compounds where water could hydrolyze ingredients or impact stability, anhydrous solvents are essential. It is often involved in:

-

Purification of active ingredients

-

Crystallization processes

-

Solvent exchange procedures

5. Polymer and Plastic Manufacturing

In the plastics and coatings industry, anhydrous acetone acts as a strong, fast-drying solvent for resins, plastics, and adhesives. Its water-free state ensures that final products cure properly without the interference of moisture, which can affect adhesion and consistency.

Anhydrous vs. Regular Acetone

| Feature | Anhydrous Acetone | Regular Acetone |

|---|---|---|

| Water Content | 0% (or trace) | May contain small amounts of water |

| Purity | High | Industrial or cosmetic grade |

| Best Use | Lab and chemical work | Nail polish remover, household cleaner |

| Cost | More expensive | Generally cheaper |

Safety Considerations

While useful, anhydrous acetone is highly flammable and should be handled with care. Proper ventilation, storage in fireproof containers, and the use of personal protective equipment (PPE) are recommended when using this chemical in any setting.

Conclusion

Anhydrous acetone plays a vital role in industries and labs where purity and dryness are crucial. From synthesizing complex chemicals to manufacturing electronic components and pharmaceuticals, it provides a dependable, water-free environment that ensures quality and precision. Although it may be more expensive than regular acetone, its unique properties make it indispensable in advanced chemical processes and high-performance applications.